Home Page

Improved solar farm output per dollar spent over farm lifetime9

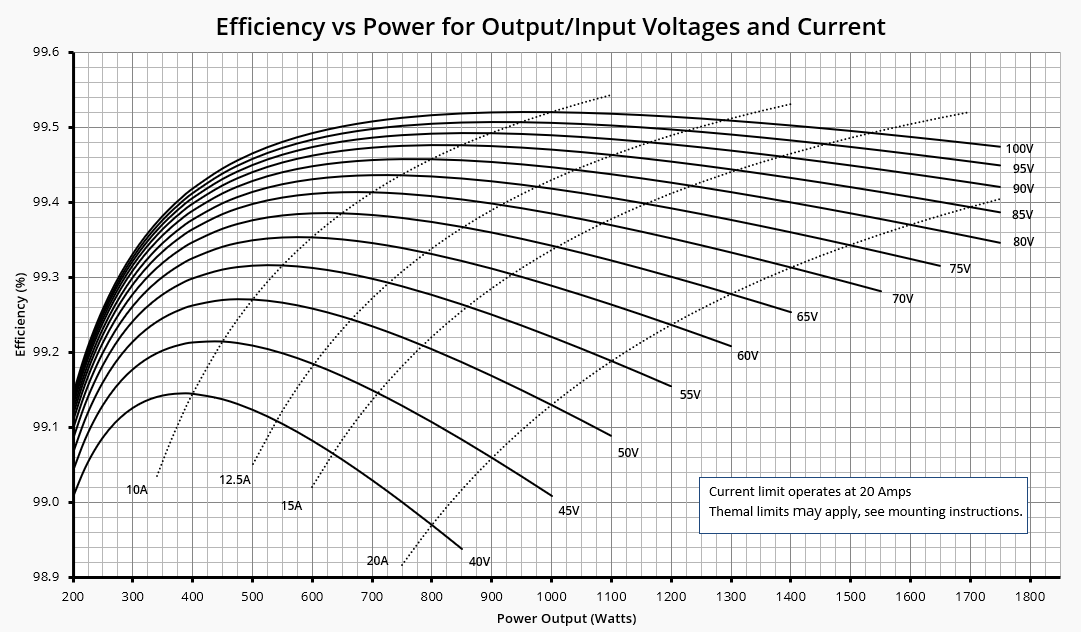

Reduce Build Cost per MWhr. CQSola 1500V Solar Power Controllers convert power at 99.2% - 99.5% efficiency, and allows each panel to operate separately. This captures power from each panel individually, and combines to each string without power loss.

Panel-level MPPT's track and fully return to the Maximum Power Point after shading typically within 2 sec. 9Subject to additional terms and conditions, not available on all farm designs, indicative build cost without CQSola Equipment over 30years is $36USD/MWHr on the DC Side vs $30USD/MWHr with CQSola Equipment on the DC Side of the inverter

Find out more

5%-25% additional power output4, same panels

1 Second Data collection, on every panel

Get 100% clarity over your solar farm. Know exactly what energy is getting outputted at every point in time. Isolate your data down to a single panel, any any second of the day. If a panel fails, needs cleaning, or starts to show electrical signs of silicon cracking, you can track it to the panel.

Almost no loss with a single panel outage

With our Solar Power Controllers in your solar farm, the maximum power will be preserved at all times. If a single panel fails, you don't lose all power from the string; just the one panel

Remove central MPPT's from design

Maximum Power point tracking is conducted by our power controllers , and able to feed directly into the inverter. Central MPPT's can be removed from the design, and replaced with CQSola Solar Power Controllers at the panel. This allows each Panel to track to Maximum optimisation and provide overall better efficiency.

Replace individual panels at any time

Each solar power controller can be set to a maximum operating voltage, so older panels can be mixed in with new panels on the same string. No bother to keep an excess of the same panel in storage

Emergency Shutdown

In natural disasters, such as floods, cyclones or electrical storms, solar farms traditionally can't be shut off. CQSola OS1000 solar power controller allow each string to be turned off remotely as needed. Entire system solar farm is possible within seconds of Emergency Shutdown switch being activated.

No-clipping between controllers

Anti Clipping technology actively takes voltage head-room from underperforming or shaded panels, and applies it to the best performing panels in real time. Never clips any power, and always remains safe.

- Red - With our optimising system: Total Power Output (read from right index)

- Orange - Without our optimising system: Total Power Output Assuming Single MPPT (Read from right index)

- Green - Individual Panel Data (Read from Left index)

- Yellow -Individual Panel Data (Read from Left index)

- Pink - Individual Panel Data (Read from Left index)

- Blue - Individual Panel Data (Read from Left index)

- Note: The day was cloudy, and the Blue Panel went under heavy cloud at 11:33. This cloud went over all panels at 11:37 and was completely lifted by 11:47

Data without Ethernet cabling2 or Wifi disturbance

We've added an in-line modem to pass all the data over the power cables. High quality, reliable data, without the extra hassle, just plug in the solar power controller, and comms start up.

Reduce lost power from aging panels

As your solar farm ages; power output gradually lowers over time due to aging panels. CQSola solar power controllers allow panels to operate separately allows ages panels to only affect themselves, and not the entire string.

Our modelling has estimated up to 25% more power during the later years of solar farm production due to differences in aged panels. Enquire below to get a model designed for your farm, or future farm.

Reduce running costs by up to %504 with our patent pending technology

Employ Staff during the Day, Safely

Introducing the world first capability of turning off a solar farm. or a single string, whichever you need at the time. This allows your staff to switch whole strings to Zero Volts1, safe to work on during the day.

No more panel grading

No more man-power needed for sorting panels. Each panel operates separately of one another, and can be put in individually. The maximum power will be preserved. If a single panel fails, you don't lose all power from the string; just the one panel

Clean Panels only when they're dirty

With one-second, individual panel data; you'll know when each panel is dirty, and only start cleaning when a panel is showing signs of performance loss, saving you man-hours and call out costs.

Reduce your inverter costs4

Without a central MPPT, the central solar farm inverter can be replaced with any Constant DC input voltage type inverter. Reducing costs significantly

Claim Warranty on broken panels

With full visible data, broken panels are quickly and easily identified, and without extra testing; can be sent back to the manufacturer within the warranty period for a replacement panel

Use second hand panels

With each panel operating separately, any panels can be used; Even second hand panels from other solar farms.

Reduce build costs; Design with overhead cables

You can read that again. With these solar power controllers active, only the single panel is affected by the shading over overhead cabling.

Allowing you to cut cabling cost substantially, and retain your output

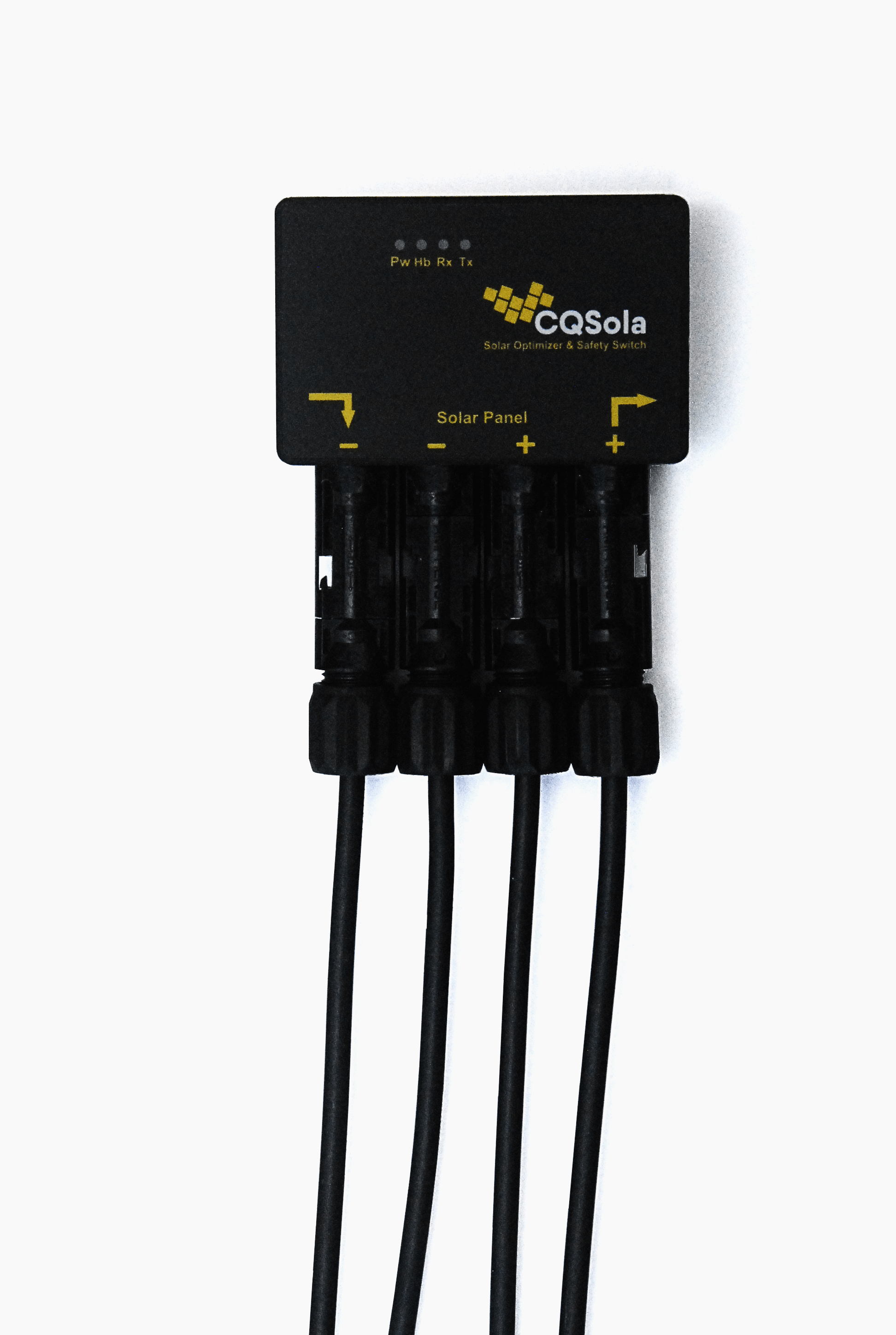

Engineered to be tough and compatible

-

IP68 Water Resistant6, and suitable for at-sea solar farms

Each power controller is completely sealed, and rated to IP68. Without any metal outside of the box, the devices can be submerged in salt water for an hour without consequence, making them ideal for at-sea solar farms

-

Designed for SIL2 Safety Certification6

SIL2 Safety certification requires 2 independent systems within the controller to continually detect the device is operating safety for it to be flagged as safe for operation. If any one system fails, the device automatically goes into shutdown.

-

Fanless

Our controllers run between 99.2% - 99.5% efficiency, with almost no heat loss, our controllers can run silent without a fan in sight.

-

On Device Data collection

We store all data on the communications units, and sync to the cloud when internet becomes available. Even with an unreliable internet connection, all the data is preserved, and pushed to the cloud when internet is available.

-

Compatible with all Batteries and Inverters

Now and in the future. The output of the CQSola solar power controllers acts like panels on the system. If the Battery or inverter can receive power from a panel, the controllers will work too.

-

Between -20°C and 70°C Degrees operating range3

For solar farms in irregular climates, our controllers will run in a wide range of conditions, from moisture heavy, hot conditions to light snow conditions.

Technical Specifications:

OS1000 Solar Power Controller

Power Curve

Parameters for OS1000 Solar Power Controller

| Panel Voltage: | 10 - 100 VDC (typically 60VDC) |

| Panel Current: | 0.05 - 20 note 1ADC (typically 8ADC) |

| Output Voltage: | 0 - 100VDC (typically 40/80VDC) |

| Output Current: | -0.1ADC - 20 note 1ADC (typically 8ADC) |

| Temperature: | -20 - 85°C (typically 45°C) |

| MPPT Time Constant: | 0.5 - 5 Seconds (typically 2 Seconds) |

| MPPT Accuracy: | 0.5% |

| MPPT Test Validation Time: | 10 seconds |

| Efficiency: | upto 99.5% (typically > 99%) |

Other Parameters for OS1000 Solar Power Controller

| Weight: | 380grams |

| Size without connectors: | 96.5mm x 62mm x 29.5mm (L,W,H) |

| Size with connectors: | 96.5mm x 99.5mm x 29.5mm (L,W,H) |

| Ingress Rating: | IP68 with cables connected note 2 |

| Safety Rating: | SIL2 note 2 |

| Electrical Safety Compliance: | IEC 62109-1 |

| Communication Channels: | 2 |

| Communication Type: | Power Line Modem |

| Mounting methods: | 3.6mm Cable Tie, Plate (standard), 4Gx12mm screws |

Note 1: Installation location temperature may reduce Maximum Output Current of the panel due to Internal thermal limiting, standard mounting plate is recommended

Note 2: Hardware and software designed to comply, approvals pending

Maximum Operating Specifications for OS1000 Solar Power Controller

| Maximum Power Transfer: | 1000 Watts |

| Maximum System Voltage: | 600/1000/1500 VDC |

| Maximum Current: | 22 Amps |

| Maximum Panel Voltage: | 100VDC |

| Maximum Output Voltage: | 100VDC |

| Minimum Panel Voltage: | 10VDC |

| Maximum Temperature: | 85°C |

| Minimum Temperature: | -20°C |

| Internal thermal limiter: | 95°C |

| Internal current limiter: | 20 Amps |

SCOM Communications & Safety Indicator Unit

Parameters for SCOM Communications Unit

| Mains Voltage: | 90VAC - 265VAC (Typical 230VAC) |

| Low Voltage DC: | 120VDC - 375VDC (Typical 200VDC) |

| Extra Low Voltage DC: | 12VDC - 120VDC (Typical 48VDC) |

| USBC Power: | 5VDC - 20VDC (Typical 5VDC) |

| CAN/DeviceNet Power: | 4.8VDC - 5.2VDC (Typical 5VDC) |

| CAN bit rate: | 10Kbps - 1Mbps (Typical 250Kbps) |

| RS485 baud rate: | 300 - 1M Baud (Typical 19200 Baud) |

| Power consumption: | 1-3 Watts |

Other Parameters for SCOM Communications & Safety Indicator Unit

| Weight: | 200 grams |

| Size: | 71.8mm x 79.8mm x 67.2mm (L,W,H) |

| Ingress Rating: | IP20 |

| Safety Rating: | SIL2 note 2 |

| Electrical Safety Compliance: | IEC 62109-1 |

| Communication Types: | Power Line Modem (2 channels), Ethernet, Wi-Fi USB, CAN Bus / DeviceNet, RS485 |

| Communication Channels: | 7 |

| Security: | Ethernet/Internet/Wi-Fi data encrypted device to server |

| Mounting methods: | 35mm (standard) DIN rail, takes four DIN rail slots |

| Data storage: | MicroSD card of any size, 64GB included by default |

| Data logging: | Logging saved to MicroSD card at one second intervals, and backed up to CQSola Cloud |

| Event logging: | Event logged to MicroSD card, backed up to the CQSola Cloud |

| Safety indication: | Flashing red and green lights |

| Safety Lockout: | E-Stop safety lockout when the Off Button is pressed. All controllers have an output voltage of zero1. E-Stop is persistent and can only be removed by pressing the On Button. |

| Diagnostic indication: | Power, Heart-beat, Comms receive, Comms transmit |

Maximum Operating Specifications for SCOM Communications & Safety Indicator Unit

| Maximum String Voltage: | 1000VDC |

| Maximum Supply Voltage: | 375VDC |

| Maximum Temperature: | 75°C |

| Minimum Temperature: | -30°C |

| Maximum OS1000 units: | 50 Device/s |

All specification and information are subject to change without notice and are given in good faith as at the date of publishing. If any specification is critical to your design please contact CQSola to discuss as there may be specifications not listed here and ways to further assist you. For 1000VDC systems, please contact CQSola for more information.